Locate Disturbances In Biogas Plants With These Tips

At first glance, the production of biogas in biogas plants is a simple matter. In fact, the process of biogas production is a very complex operation. Not only does the biological degradation of large organic substances into biogas require a great deal of attention, but the structural and mechanical equipment is also subject to wear and tear that can lead to malfunctions. In this post, we will discuss potential reasons for disturbances in biogas plants.

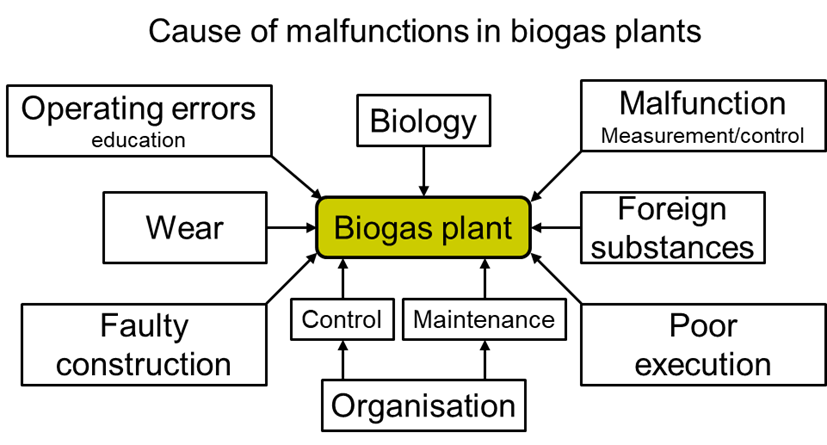

The illustration provides an overview of the various influences that exist on the biogas production process. It is easy to understand that the risk of disturbances is always present.

Disturbances in biogas plants can have many causes. Not only the biological core process is affected. Pumps, agitators, conveying equipment can wear out and cause malfunctions. Malfunctions of measuring instruments and in the control, the system can lead to considerable problems. In addition, there are errors in design and construction. Insufficient control and maintenance lead to avoidable malfunctions.

Impairments in the operation of a biogas plant can result from

- Disturbances in the biological process

- Malfunctions caused by foreign substances

- Malfunctions caused by wear and tear on the machines, pipelines, tanks, etc.

- Malfunctions caused by malfunctioning of measuring devices and electrical controls

- Malfunctions caused by faulty design

- Malfunctions caused by faulty design

- Malfunctions caused by human error

Malfunctions of the biological process are usually caused by

- Incorrect operation (too much / too little addition of substrate

- One-sided substrate composition → lack of macro and or micronutrients

- Toxins

Mechanical disturbances are caused by

- Foreign matter such as stones, plastic, metal (damage to pumps, blockages)

- Excessive dry matter content (formation of floating layers, insufficient mixing, wear on agitators and pumps)

- Insufficient comminution of the substrate (blockages)

Malfunctions caused by faults in measuring devices and the control system

- Installing installed measuring devices incorrectly or not maintaining and calibrating measuring devices regularly can produce incorrect results. These can lead to incorrect subsequent reactions.

Design errors, defective designs

- Poorly designed equipment leads to high energy consumption and wear as well as malfunctions. Mixing and agitating technology is particularly affected by this.

- Poor construction such as leaky tanks, poor welds and the like can lead to malfunctions and higher maintenance costs.

Human error

- Operating errors that occur due to stress or ignorance can have devastating consequences. We can never completely avoid misbehaviour but we can reduce mistakes through design measures. Staff training also helps to reduce this risk

Preventive maintenance

- Well-organised control and maintenance can keep the plant components, especially all mechanically stressed components (pumps, agitator technology, gas engines) constantly ready for operation. In this way we can reduce failure due to malfunctions significantly.

What can Celsigas offer?

We can provide our customers with competent advice on all aspects of troubleshooting in the event of acute problems. We can also optimise the biogas plants for long-term operation. The optimisation does not only refer to the actual biological process. All process engineering, mechanical and electrical components are affected. The declared aim is to

- Improve operational safety

- Maximise gas yield and energy production

- Maximise operating times

- Minimise downtimes due to malfunctions

- Reduce own energy demand

- Minimise wear and tear and the need for spare parts

We can make extensive recordings of the biogas plant and develop detailed proposals for optimising the operation on this basis. During the implementation, we can check the success so that in the end there is a technically and economically positive result. We can provide training on all aspects of biogas technology. Safety instructions for staff to increase working and operational safety are part of our range of services.

Our engineers with many years of experience in biogas technology are available to you to locate and eliminate disturbances in biogas plants.

0 Comments