Trace Elements – Key to stable production of biogas

The production of biogas from organic material is caused by a diverse collective of bacteria. The bacteria require the supply of “basic food” and the supply of essential substances. This is to ensure healthy nutrition. If the bacteria in the production of biogas find optimal living conditions, they can fully utilize the substrate and ensure maximum gas production. How can the addition of trace elements improve biogas production?

External living conditions

The production of biogas is a very complex process. The degradation of biomass consists of a wide variety of macromolecules.

A digester as the habitat of the bacteria represents the external prerequisite for the biogas process. The substrates from which the biogas is to be produced are placed in the digester. The bacteria cause the transformation of the substrates to the biogas. As a result, the biogas is collected at the digester head and can be recycled.

The digester must be able to provide uniform nutrient-, bacteria-, and temperature distribution.

Internal living conditions

The digester itself is the workshop of the bacteria. In this workshop, there must be a sufficient number of workers to be able to achieve the desired production goal.

The bacteria involved need a part of the biomass of the substrate for nutrition and regeneration. This proportion depends on the composition of the substrate. Carbohydrates require about 5%, proteins 7.5%, and fats 15% of the amount of substrate or energy used [2]. This determines the number of bacteria present in a biogas plant at equilibrium. The composition of the bacterial culture can vary over a wide range. The macronutrients nitrogen, phosphorus, potassium, sulphur and magnesium are necessary for the development and maintenance of bacteria.

Overview of the nutrients involved

Carbon, as the central building block of organic chemistry, is the main component of substrates and bacteria. The end products produce methane and carbon. Methane production is not possible without the presence of organically bound carbon. The other main nutrients are nitrogen, phosphorus, oxygen and sulphur. Oxygen is not a nutrient in the strict sense but is an important component of the substrates, the cofactors and the end products. Hydrogen is present in practically all substrates and in water.

Macronutrients

| Element | Occurrence | Task | |

| Carbon | C | Biomass of plant and animal origin | Carbon is a basic building block of bacterial cellular material. When a carbon-containing compound is oxidized or reduced, the reaction generates energy. Since organic substrates are carbon-rich, carbon will generally not be a limiting nutrient. |

| Nitrogen | N | Protein, Uric Acid, Urea, Ammonium / Ammonia, Creatine | Nitrogen is the primary nutrient required for the microbial synthesis of proteins. Limits protein synthesis Required for PEP synthetase activity. |

| Phosphorus | P | Nucleic acids, phospholipids, nucleotides (ATP, GTP, NAD+, FAD) | Restricts nucleic acid synthesis and/or energy production |

| Sulphur | S | Cysteine, methionine, thiamine pyrophosphate | Limits protein synthesis. Required for the activity of PEP synthetase. |

| Sodium | Na | Important extracellular cation | Counter ions to cell buffers, electrolytes and DNA, solutes for exchange and transport processes, and energy production. |

| Potassium | K | Important intracellular cation, a cofactor for some enzymes | Potassium is involved in the active transport of compounds across the bacterial membrane, e.g., the transport of nutrients and cation balancing. Limits nucleic acid synthesis and/or cell wall and/or cell membrane structure or permeability. |

| Magnesium | Mg | Important divalent cellular cation | Inorganic cofactor for many enzymatic reactions, including ATP. Limits nucleic acid synthesis and/or cell wall and/or cell membrane structure or permeability. Enzyme activator for kinases and phosphotransferase. |

Essential trace elements are iron, nickel and cobalt, which are indispensable for methanogenesis. Sodium, potassium, magnesium and calcium, as quantitatively significant substances, are directly and indirectly beneficial for a number of processes. Positive effects are assumed for the elements boron, aluminium, vanadium, manganese, copper and iodine, even though their mechanism of action has not been sufficiently clarified.

Micronutrients

| Element | Task | |

| Boron | B | Boron is critical for cell wall and membrane integrity. |

| Calcium | Ca | Required for the stability of methyltransferase and aggregation of cells, and also needed for the stability and activity of cellulases, amylases, lipases, and proteases |

| Iron | Fe | Required for the activity of ATPase, PEP carboxylase, and serine transhydroxymethylase. |

| Cobalt | Co | Required for the synthesis of vitamin B12 (cyanocobalamin) Metallic enzyme activator Activates carboxyl peptidase |

| Copper | Cu | Metallic enzyme activator Cu can inhibit metabolism Chelates other substances and reduces their toxicity Superoxide dismutase and hydrogenase in methane-producing bacteria, facultative anaerobes and clostridia |

| Manganese | Mn | Specific enzyme activator, fatty acid synthesis |

| Molybdenum | Mo | Inhibitor of sulphate-reducing bacteria Cofactor of various flavinous enzymes |

| Nickel | Ni | Synthesis of coenzyme A Factor F430 CH3-CoM reductase Stabilizes DNA, RNA Cofactor of urease Stabilization of cell membranes |

| Selenium | Se | Hydrogenase, FDH in methane-producing bacteria and clostridia. |

| Vanadium | V | |

| Tungsten | W | |

| Zinc | Zn | Metallic enzyme activator Activates carbonic anhydrase and carboxyl peptidase A Stimulates cell growth Cofactor of RNA and DNA polymerase Zn can exacerbate the toxic effects of other metals and inhibit metabolism Hydrogenase in methane-producing and sulphate-reducing bacteria |

A diet should be balanced in composition. The substrates should have an optimal composition of carbohydrates, proteins and fats. The main nutrients C, H, P and K should be in a balanced ratio.

Moreover, malnutrition should be avoided. Excessive food intake can lead to disorders.

Too high a concentration of organic acids will lead to.

- Damage to bacteria and disruption of gas production.

- Inadequate utilization of substrates will result.

Too high a concentration of ammonium/ammonia will result in damage to the bacteria and disruption of gas production. The source of ammonium is a high proportion of protein in the substrate.

Malnutrition

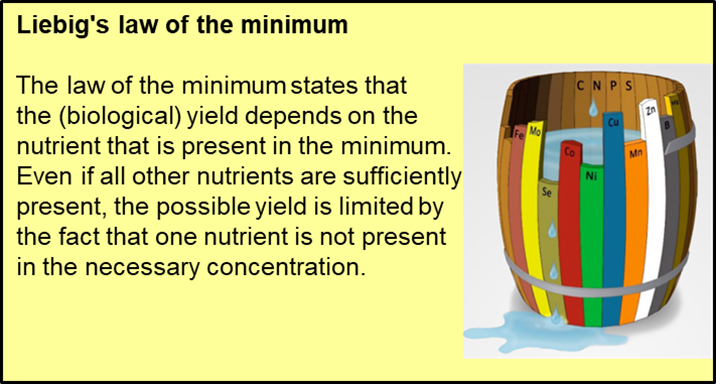

Malnutrition is a deficiency of trace elements that leads to insufficient degradation of substrates. Consequently, it should be avoided.

The concentration of bacteria necessary for the degradation of the substrates cannot be formed from a deficiency of essential trace elements.

A deficiency of trace elements can have various causes. The composition of the substrates can be very one-sided. For instance, substrates from the processing of carbohydrate-containing substances such as cassava, rice, and comparable source products are not only low in nitrogen. Trace elements in plants, and indirectly in animal products, are absorbed through the soil.

If there are not enough trace elements in the soil, the plant cannot sufficiently absorb them. Meanwhile, the uptake of trace elements depends on the plant species and the plant’s requirements. The requirements of the plant for the quantity and quality of trace elements are not identical to the requirements of the bacteria in the production of biogas.

Availability of trace elements must be present to pass through the cell wall to be able to incorporate them into enzymes. These enzymes cause a degradation of the biomass to biogas.

The trace elements, which are often metals, must be present in dissolved form or bound in complex compounds. If the metals form insoluble compounds when reacting with sulphides, it means there is an undersupply in the digester.

Macronutrient requirements

Nutrients are to ensure the supply of the bacteria in biogas formation. The elemental composition can be used to infer the demand for nutrients. The composition of the bacteria from the digester can be described on average by the molecular formula C60H87O23N12P1.2S0.38

Scherer gives the recommendation to determine the nutrient composition.

C : P : N : S = 2.000 : 15 : 5 : 3

For many substrates, it will be more advantageous to state the ratios in terms of chemical oxygen demand (COD). It should be considered that the macronutrient demand differs according to the groups of substances. (For example; carbohydrates require more nutrients compared to fats and proteins).

CODdegradable : N : P : S = 300 : 5 : 1 : 0.5

Lower concentrations are required for fats and proteins

CODdegradable : N : P : S = 800 : 5 : 1 : 0.5

The higher demand for the breakdown of carbohydrates is explained by the greater speed of breakdown [1].

Need for micronutrients

The addition of micronutrients may be necessary if the substrates cannot supply these micronutrients in sufficient quantities. The addition should compensate for the deficit to ensure an optimal supply. However overdosing must be avoided. If the concentration is too high, any metals can inhibit the process or have a toxic effect.

The tables below are from various sources and indicate how many trace elements must be present to ensure the degradation of one kilogram of COD to biogas. The first table shows the concentrations per litre of digester volume required to degrade 50 g COD/l.

These are only a few, general compilations on the need for biologically available trace elements to be able to ensure long-term stable operation of anaerobic fermentation. The above tables reflect the current state of knowledge.

A thermophilic mode of operation requires a greater demand for trace elements. The quantitative requirements for the need for trace elements follow as a rule in this sequence: Fe > Ni/Co > Mo (and/or) W > Zn > Cu/Mn.

Effect of trace elements

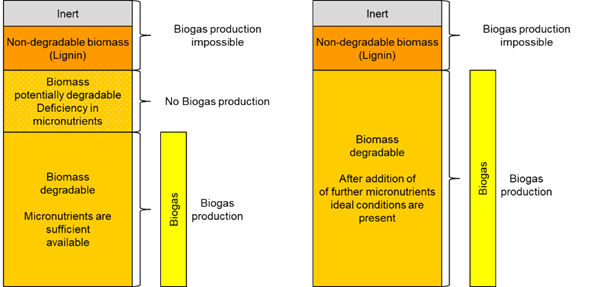

If all nutrients and trace elements are available to the bacteria in sufficient quantity and quality, the available biomass can be converted to biogas to the maximum extent.

The effect can be easily demonstrated in a standardized fermentation test. The substrate in question is subjected to a fermentation test. Two tests are carried out in parallel. One sample is treated as per standard. The second sample on the other hand is treated with the addition of trace elements. The gas quantities as a function of time are recorded, compared and observed.

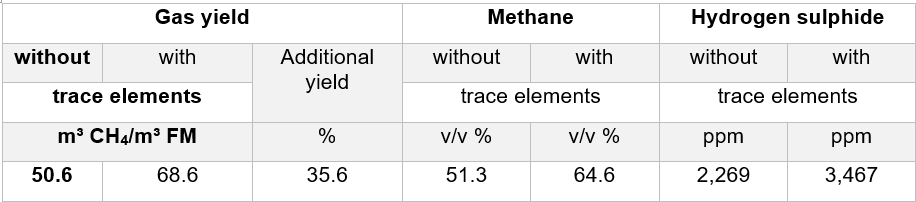

Example: Fermentation with and without trace elements

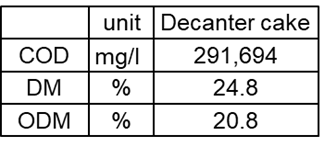

In a fermentation test with Decanter Cake from the production of a palm oil mill in the south of Thailand according to VDI 4630, a double determination was made. One test was carried out with the untreated material. The parallel test was carried out with the addition of a nutrient solution.

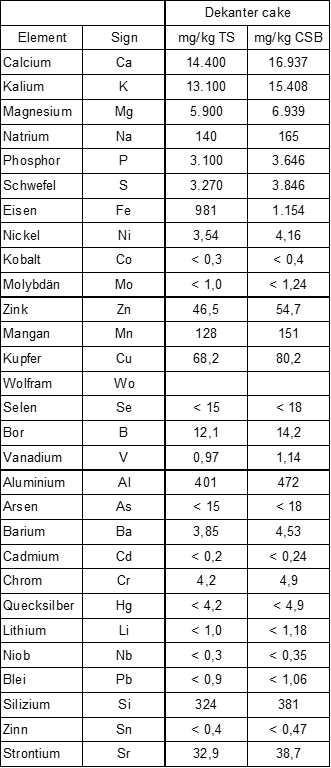

In addition, a determination of the trace elements is also carried out. The proportion of cobalt and molybdenum is clearly too low. Iron and zinc are in principle sufficiently available. However, it will not be biologically available because the sulphur content is relatively high.

The gas yield of Decanter cake with and without trace elements

The difference between the gas yields is striking. Trace elements lead to a significant increase in gas yield. Not only the gas quantity increases significantly, but also the gas quality is clearly better. The fact that anaerobic fermentation proceeds better can also be seen from the increase in hydrogen sulphide. Gas production is also slightly faster in the presence of trace elements.

The stepped degradation curve can be explained by the high content of proteins and fats in the substrate (Diauxia).

How can trace elements be added to the biogas plant?

The trace elements only have an effect if they are biologically available. Therefore, it is necessary to prepare the trace elements in such a way that they cannot react to form poorly soluble compounds.

Acinor 1000 complexes the trace elements. These trace elements consist of complexing agents, (the chelates) made available in a bioavailable form.

The trace elements are provided in a solution. In small quantities, the trace elements can be easily and safely added to the biogas plant. The trace elements are stable within the biogas plant and can be provided to the bacteria at low dosages with high efficiency.

What is the demand for trace elements?

Trace elements must be added to the digester/post-digester on a regular basis.

As a guideline for the production of

1 MW of electrical power with the addition of 0.8 l Acinor 1000 per day

Or for the gas production of

15,000 m³ biogas per day = 1 l Acinor 1000 per day

For the start-up, it requires a higher addition:

One-time addition of 20 l Acinor per 1 MW of electrical output

or

15,000 m³ of biogas per day = 28 l of Acinor

An analysis of the trace elements present is not necessary. Its results do not necessarily reflect the real situation. The bioavailability is usually not recorded. The addition of the recommended amounts is sufficient without overdosing.

Costs and yields with the use of trace elements

The use of trace elements can provide an increase in gas production. Other advantages;

- Stabilization of the degradation process.

- Improvement of the space load

- Increase in space load

- Decrease in residence time

- Increase in performance of existing biogas plants

- Increase of COD degradation in highly loaded wastewater.

- Reduction of the COD concentration in the effluent

- Increase in gas yield

- Reduction of wastewater purification

Example

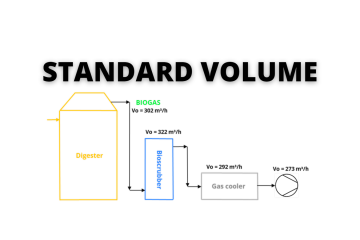

Biogas from Spentwash (effluent from alcohol production).

Results from a fermentation test:

| Yields methane | m³ CH4/kg COD | v/v % CH4 |

| Without the addition of trace elements | 0.175 | 63 |

| With the addition of trace elements | 0.200 | 64 |

COD concentration Spentwash: 150 kg COD/m³.

| Biogas yields | kg COD/m³ | m³ CH4/kg COD | m³ CH4/m³ | m³ Biogas/m³ |

| Without addition | 150 | 0.175 | 25.25 | 41.6 |

| With addition | 150 | 0.200 | 30.00 | 46.8 |

If the gas engine is to generate an output of 1 MW of electrical energy = 24 MWh/day at an efficiency of the gas engine of 40 %.

2,500 kWh/h = 60,000 kWh/day of energy required

| Energy yields | m³ CH4/m³ | kWh/m³ | Demand fuel (kWh/day) | m³ Spentwash/day |

| Without addition | 25.25 | 9.971 | 60,000 | 238.8 |

| With addition | 30.00 | 9.971 | 60,000 | 200.4 |

→ Increase in gas yield: ≈ 12.5 %.

Demand Acinor for the production of 1 MWel = 0.8 litres/day

| Cost | 60 US$/litres |

| 48 US$/day |

The generated amount of electrical energy

| m³ Spentwash/day*MW | kWh/day | |

| Without addition | 238.8 | 24,000 |

| With addition | 200.4 | 28,874 |

Additional income 4,570

| Value of kWh | 0.08 US$/kWh |

| 365.60 US$/day |

Do you want to learn more about trace elements, head over to our products page for Celsigas Trace Elements or contact us!

NON-BINDING EXAMPLE

[1]

ATV-Fachausschuss 7.5 “Anaerobe Verfahren zur Behandlung von Industrieabwässern”: Anaerobe Verfahren zur Behandlung von Industrieabwässern, Korrespondenz Abwasser, 37, 1247-1251, 1990

[2]

Scherer, Paul A.: Biogastechnik-Grundlagen und Besonderheiten der anaeroben Prozeßführung, Biogas-Anaerobtechnik in der Abfallwirtschaft, Thome-Kozmiensky (Hrsg.) Berlin 1989, 1 – 36

[3]

van Hullebusch, Eric D.; Gilles Guibaud; Stéphane Simon; Markus Lenz, Sepehr Shakeri Yekta; Fernando G. Fermoso; Rohan Jain; Lars Duester; Jimmy Roussel; Emmanuel Guillon; Ulf Skyllberg; C. Marisa R. Almeida; Yoan Pechaud; Mirco Garuti; Luigi Frunzo; Giovanni Esposito; Cynthia Carliell-Marquet; Markus Ortner: Gavin Collins

Methodological approaches for fractionation and speciation to estimate trace element bioavailability in engineered anaerobic digestion ecosystems: an overview.

Critical reviews in environmental science and technology, 46(16) 1324-1366, 2016

0 Comments