Gas Analysis

Intelligent process monitoring and control can essentially determine the profitability of a biogas or syngas plant. In addition to the process parameters in the reactors, a reliable and precise gas analysis of the gas production and quality is required for a safe operation of the cogenerators.

The gas composition in agricultural biogas plants varies depending on the process and composition of feedstock. Our clients require biogas quantity and quality measurement after the individual fermenters or at the flare. The measured values provide information for for filter monitoring in gas purification and before consumers such as boiler and CHP. Another application is monitoring the quality of the supplementary air from the double membranes of the fermenter covers.

Gas analysis and gas flow measurement systems for portable and stationary operation – for the qualitative and quantitative analysis of biogas, digester gas, landfill gas, air and exhaust air.

In sewage treatment plants, the gas quality is only subject to minor fluctuations. Our clients use our products to monitor the quality of the digester gas after the H2S filter. Clients also require a continuous monitoring of the flow rate. The measurements give information about when to replace the filter material, instead of needing to schedule periodical replacements.

Prior to the treatment in scrubbers and filters it is important to measure and analyze the exhaust air from covered tanks and closed rooms with screening or sludge thickening equipment.

In gasification it is equally important analyse syngas is for process monitoring and CHP protection. Process conditions must be stable to prevent formation of tar.

Landfills use analytical technology for long term monitoring of individual fields or for monitoring the landfill gas quality in the collection pipeline.

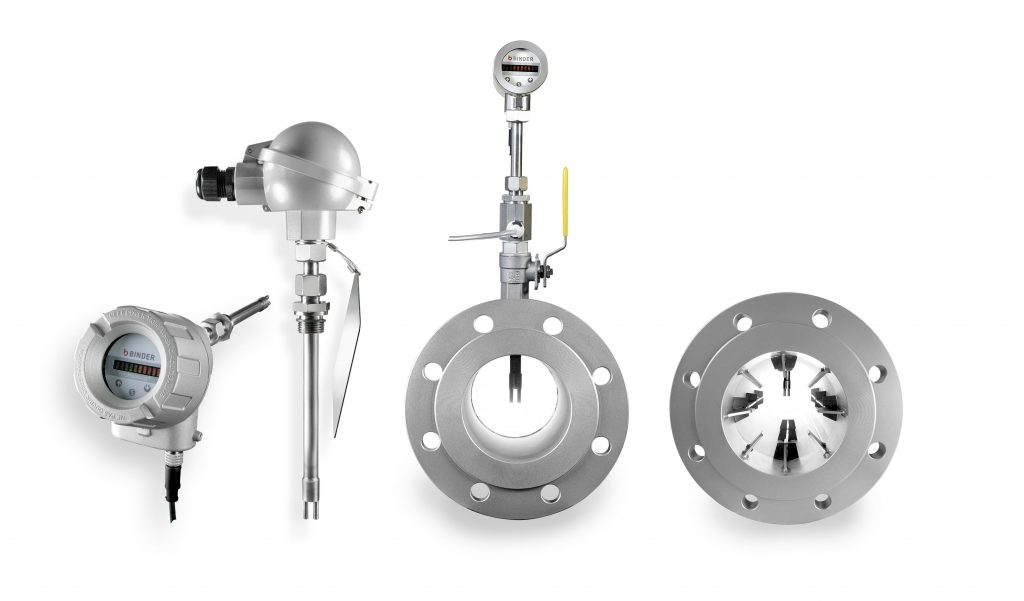

Gas Flow Meters

Gas Analysers

Data Stations